In today's fast-paced world, where accuracy and efficiency are incredibly important, finding the right tools can make all the difference. It's almost as if some technologies shine brighter, offering a clear path forward in what can sometimes feel like a very complex industrial landscape. That's where helios injection systems come into the picture, standing out as a true beacon for precise material delivery. We're going to explore just what makes these systems so compelling and why they might be exactly what many operations are looking for right now.

You know, much like Helios, the ancient Greek god of the sun, who was crowned with rays of golden sunlight and rode his blazing chariot across the sky, these systems represent a kind of focused power. They bring a level of control and consistency that is rather remarkable, aiming to illuminate processes that might otherwise be a bit dim or unpredictable. It’s about bringing that sun-like reliability to your work, every single day, more or less.

This article will take a closer look at helios injection systems, discussing their core features, the many ways they can be used, and the significant advantages they bring to different fields. We'll also touch upon how they align with current trends, ensuring your operations stay ahead of the curve. So, let's see how these systems can help light up your productivity and bring a new level of accuracy to your tasks.

Table of Contents

- What Are Helios Injection Systems?

- The Advantages They Bring

- Where Helios Systems Make a Difference

- Staying Current with Helios Technology

- Frequently Asked Questions About Helios Injection Systems

- Looking Ahead with Helios

What Are Helios Injection Systems?

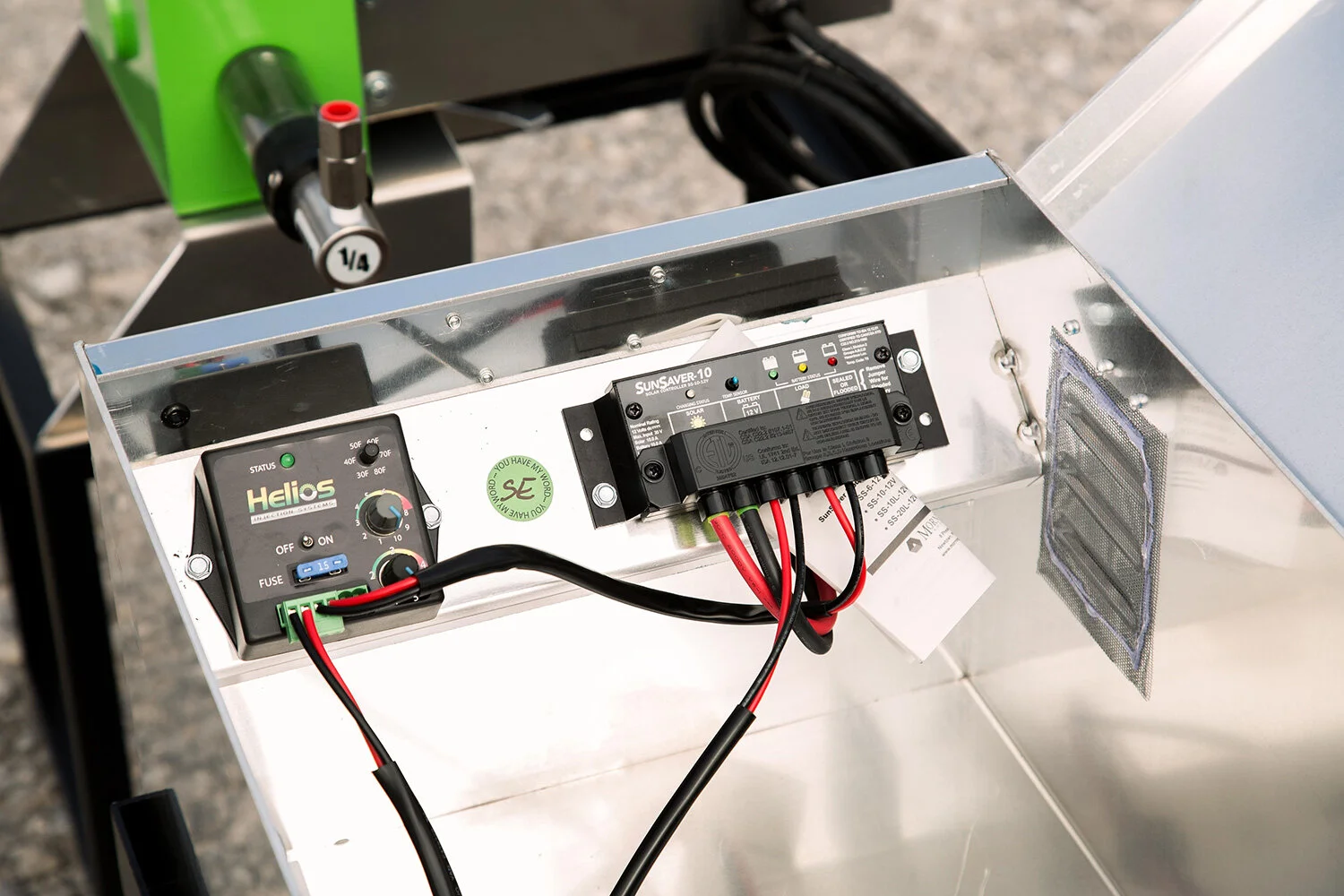

Helios injection systems are, in essence, advanced tools designed for the very precise and controlled delivery of various materials. They are built with a focus on delivering substances with incredible accuracy, whether that's a tiny drop of a chemical or a steady flow of a liquid. This kind of system is usually quite sophisticated, using smart technology to make sure everything goes where it should, exactly when it should. It’s about taking the guesswork out of important processes, you know.

Inspired by Ancient Mythology

The name "Helios" itself, as a matter of fact, brings to mind the powerful sun god from Greek mythology. Helios, the son of Hyperion and Theia, was the personification of the sun and a god of the day. He was known for his blazing chariot and the golden sunlight he brought, which represented clarity, power, and consistent presence. This mythological connection hints at the core qualities of these injection systems: they aim to bring that same level of powerful, consistent, and clear performance to industrial and scientific tasks. It’s a bit like harnessing the sun's reliability for your operations, which is pretty cool.

Just as Helios represented a consistent daily journey across the sky, these systems are built for steady, dependable operation. They are designed to avoid the kind of chaotic events that Phaethon, the mortal child of Helios, faced when he lost control of his father’s divine chariot. Instead, helios injection systems prioritize maintaining control, ensuring that every injection is made with precision and without deviation. This focus on controlled delivery is, arguably, a key aspect of their appeal.

Core Principles of Operation

At their heart, helios injection systems typically operate on principles that prioritize meticulous measurement and controlled release. They often use a combination of advanced sensors, smart pumps, and sophisticated software to manage the flow and volume of materials. This means that whether you need a micro-dose or a larger, continuous stream, the system can deliver it with remarkable consistency. Basically, it’s about making sure the right amount goes to the right place, every time, which is really important.

These systems are also built with a certain adaptability in mind. They can handle a wide array of liquids, gels, and sometimes even very fine powders, making them quite versatile for different applications. The engineering behind them usually aims for durability and long-term reliability, so they can keep working effectively even in demanding environments. You can, for instance, often find them in places where precision simply cannot be compromised, like in a laboratory or a busy production line.

The Advantages They Bring

When we talk about the benefits of helios injection systems, it's about more than just doing a job; it’s about doing it better, faster, and with less waste. These systems are designed to improve several aspects of an operation, leading to tangible gains. They represent, in a way, a step forward in how many industries handle their critical material delivery tasks. There are, for instance, some very clear advantages that stand out.

Unmatched Accuracy and Consistency

One of the biggest draws of helios injection systems is their incredible accuracy. They can deliver exact amounts of material repeatedly, which is crucial for quality control and product consistency. This kind of precision helps reduce errors and ensures that every batch or every product meets the same high standards. It’s like having a very steady hand, but on a much larger scale, and that consistency is something businesses really value, you know.

This consistent delivery also means less variation in the final product. For instance, in manufacturing, if a specific amount of adhesive or lubricant needs to be applied, these systems ensure it's always the same. This reduces rework, cuts down on defects, and ultimately leads to a higher quality output. It’s a bit like the sun reliably appearing each day; you can count on the system to perform with similar dependability, more or less.

Boosting Operational Efficiency

Beyond accuracy, helios injection systems significantly boost how efficient operations can be. By automating precise material delivery, they free up human workers for other tasks and speed up production cycles. This means more output in less time, without compromising on quality. It's about working smarter, not just harder, which is something many businesses are looking for right now, apparently.

The speed at which these systems can operate, coupled with their precision, means that processes that once took a long time or required constant oversight can now be completed much quicker and with less direct human intervention. This leads to smoother workflows and a more streamlined production line. They are, in fact, quite good at keeping things moving along without a hitch, which is always a plus.

Cost Savings and Resource Optimization

By delivering materials with such exactness, helios injection systems help minimize waste. When you use only what you need, you save on raw material costs, which can add up to significant savings over time. This is particularly important for expensive or scarce materials, where every drop counts. It’s about being smart with resources, and that really makes a difference to the bottom line.

Reduced waste also means less cleanup and disposal, which can further lower operational expenses. Plus, the reliability of these systems often means less downtime for maintenance or error correction, leading to more productive hours. So, in many ways, they pay for themselves by making operations leaner and more sustainable, which is, honestly, a very appealing prospect for any business.

Where Helios Systems Make a Difference

The applications for helios injection systems are surprisingly wide-ranging, showing their versatility across different industries. From large-scale manufacturing to very delicate laboratory work, these systems find their place wherever precise material handling is a must. They are, in fact, quite adaptable, which allows them to solve a variety of challenges in many different settings.

Automotive and Manufacturing

In the automotive sector, for example, helios injection systems are used for applying sealants, lubricants, and adhesives with pinpoint accuracy during assembly. This ensures the integrity and durability of vehicle components, contributing to overall product safety and performance. They help make sure that every part is put together just right, which is incredibly important for cars and other complex machines, you know.

Similarly, in general manufacturing, these systems can be found in lines producing everything from electronics to consumer goods. They precisely dispense glues, resins, and coatings, ensuring uniform application and reducing material consumption. This leads to higher quality products and fewer rejects, making the entire production process more reliable and cost-effective. It's about bringing that sun-like consistency to every single item produced, which is pretty neat.

Medical and Pharmaceutical

The medical and pharmaceutical industries demand the highest levels of precision and sterility. Helios injection systems are well-suited for these environments, where they can accurately dispense active pharmaceutical ingredients, create precise dosages for medications, or apply biocompatible coatings to medical devices. The health and safety of people often depend on this kind of accuracy, so it’s a very critical application, really.

For instance, in the creation of new drugs, exact measurements are absolutely essential for research and development. These systems provide the kind of controlled environment needed for such delicate tasks, ensuring that experiments are reproducible and results are trustworthy. They help researchers push the boundaries of what's possible in medicine, which is, honestly, quite inspiring.

Food and Beverage Processing

In the food and beverage industry, helios injection systems help with the precise addition of flavorings, preservatives, and colorings. This ensures product consistency, adheres to strict recipe formulations, and maintains quality across different batches. It’s about making sure that every bite or sip tastes just right, every single time, which is something consumers definitely appreciate, apparently.

They also play a role in packaging, accurately filling containers with liquids or semi-liquids, minimizing spills and waste. This not only improves efficiency but also ensures that products are presented cleanly and professionally. So, whether it's adding a dash of spice or filling a bottle of juice, these systems bring a new level of control to the process, which is, in a way, quite impressive.

Agriculture and Beyond

Even in agriculture, helios injection systems are starting to make a mark. They can be used for precise application of fertilizers, pesticides, or even water in controlled environments, ensuring that plants receive exactly what they need, without excess. This helps reduce environmental impact and optimize crop yield. It's about growing things smarter, you know, which is becoming more and more important for our planet.

Beyond these specific examples, the potential for helios injection systems extends to any field where controlled, accurate material delivery is a challenge. Their ability to handle different substances and integrate with existing processes makes them a valuable asset for innovation and problem-solving. They are, quite literally, helping to shape the future of many different industries, which is, actually, a very exciting prospect.

Staying Current with Helios Technology

The world of advanced technology is always moving forward, and helios injection systems are no exception. Manufacturers and researchers are continually looking for ways to make them even more precise, more efficient, and more adaptable. This means keeping an eye on new developments and how they might apply to your specific needs. It’s about staying one step ahead, more or less, in a rapidly changing environment.

Current trends often point towards greater automation, smarter sensors, and better integration with other digital systems. This allows for real-time monitoring and adjustments, making the injection process even more responsive and reliable. For example, some systems are now incorporating artificial intelligence to predict and prevent potential issues before they even happen. You can learn more about advanced dispensing technologies on our site, and link to this page for further insights.

Looking at Google Trends for related terms like "precision fluid dispensing" or "automated material application" shows a steady interest, suggesting that businesses are increasingly seeking out solutions that offer greater control and efficiency. This indicates a growing demand for technologies like helios injection systems, which promise to deliver just that. It's a clear sign that the market values accuracy and reliability, which is, honestly, a very good thing for these systems.

Frequently Asked Questions About Helios Injection Systems

People often have questions when they first encounter advanced technologies like helios injection systems. Here are a few common ones that might help clarify things for you.

What types of materials can helios injection systems handle?

These systems are designed to work with a very wide range of materials. This includes various liquids, from very thin solvents to thick oils, as well as gels, pastes, and sometimes even very fine powders. The specific type of material depends on the system's configuration and the nozzles used, but they are generally quite versatile, which is, actually, a big plus for many operations.

How do helios injection systems ensure such high precision?

High precision in helios injection systems comes from a combination of factors. They often use highly accurate pumps, precise valve controls, and advanced sensor feedback loops. These components work together with sophisticated software to monitor and adjust the flow in real-time, ensuring that the exact amount of material is dispensed every time. It’s about constant monitoring and adjustment, which is, frankly, what makes them so good at what they do.

Are helios injection systems difficult to integrate into existing production lines?

While any new technology requires some planning, helios injection systems are often designed with integration in mind. Many come with modular components and flexible software interfaces that allow them to connect with existing machinery and control systems. Manufacturers usually provide support to help with the setup, making the transition as smooth as possible. So, it's generally not as challenging as one might think, which is, honestly, a relief for many businesses.

Looking Ahead with Helios

Helios injection systems are, in a way, a testament to how far technology has come in helping us achieve greater control and efficiency. Much like Helios, who consistently brought the day's light and warmth, these systems offer a dependable and powerful solution for precise material delivery across countless industries. They are helping businesses not just meet, but exceed, their quality and productivity goals. We are, in fact, seeing more and more adoption of such precise methods every day.

Considering the ongoing need for accuracy, waste reduction, and increased output, the future looks very bright for helios injection systems. They represent a smart investment for any operation looking to refine its processes and gain a competitive edge. It's about choosing tools that empower you to do your best work, consistently and reliably. To explore more about the impact of precision technology, you might want to check out resources like a leading industrial technology publication for broader insights into industry advancements.